Horizontal Flow Wrap Machine can Pack avariety of solid products of differentshapes & sizws with all types of heatsealable films and laminators. Thesemachines are extensively used to packAppalams, Rusks, Biscuits, Bun, Chocolatebars, Ice Cream Bars, Cakes, groundnutchikkies, cotton & Bandage Roles, ScrubPads, Noodles Etc.

Key Features

Cantilever construction that provides for easy clinical and electrical components

Left to right operating direction

Rotary cross sealing jaws

Self-centering film reel holder with a operated brake system

Adjustable film folding box

For every cut length we should change timing gear wheel

Eye mark setting should be done for every cut length

If sensor misses the eve mark sensation correction should be done manually by using the forward button or else the eye mark setting should be done from the beginning

Technical Specifications

Operation

Electro Mechanical

Feeding Style

Manual

Packing Style

Pillow Type Centre Seal

Product Size

Width 30 mm to 100 mm, Length 30 mm to 150 mm

Height 05 mm to 50 mm

Packing film size

Width 100 mm to 300 mm, Cut Length 75 mm to 200 mm

Production Output

Approx 20 to 80 Packs / minutes (Depending up on Product Size)

Packing Material

All type of laminated (BOPP, LD Polyester, Aluminum Foil)

Motor

1/2 HP Three Phase 440V, 50Hz

Heater

220v, 1400 watts

Power

2 kw

Machine Dimension

Length 2850 mm, Width 1000 mm, Hight 1500 mm Approx

Machine Weight

500 kg Approx

Applications

Flow Wrap machine has the following applications

Candy

Packing

Cookie

Packing

Dates Bar

Packing

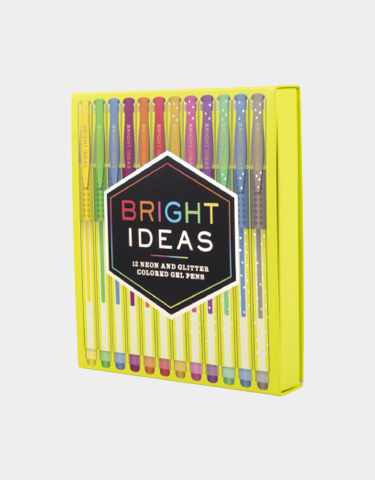

Pencil

Packing

Ball Point Pen

Packing